clutch its types design construction & working with new technology

Clutch

its types Design construction & working with latest technology

1. Power transmission:

The power developed by the

engine in automobiles should be transmitted to the road wheel efficiently. The

power transmission system basically needs a clutch to transmit the power from

the engine to the remaining parts of the transmission. The power transmission

system is different for different types of vehicles.

In case of two wheelers with

gears the power is transmitted from the clutch to the gearbox and then

transmitted to the wheels by means of chain drive or gear drive. In case of

non-geared two wheelers the power is transmitted from the clutch directly to

the wheels through the chain drive / gear drive or sometimes through the

variation mechanism.

In case of LMVs and HTVs the power

transmission consists of clutch and gearbox as the common features. In the

conventional (front engine rear wheel drive) the power is transmitted from

gearbox to road wheels by means of universal joint, propeller shaft, sliding

joint, differential and half shaft. In case of front engine front wheel drive

transaxle is commonly used. In this case the gear box is arranged transversely

and power transmission may not be provided with propeller shaft and bevel gear

arrangement. This type of arrangement is compact and also contains less number

of moving parts. In the case of four wheel drive, the arrangement is similar to

conventional power transmission with transfer gear box or transfer case as the

additional features. The transfer gear box transmits the power to both the

axles uniformly.

Power transmission

1.

Clutch

A

clutch is a mechanism which enables the rotary motion of one shaft to be

transmitted at will to second shaft, whose axis is coincident with that of

first.

·

Clutch is located

between engine and gear box. When the clutch is engaged, the power flows from

the engine to the rear wheels through the transmission system and the vehicle

moves.

·

When the clutch is

disengaged, the power is not transmitted to the rear wheels and the vehicle

stops, while the engine is still running.

Clutch is

disengaged when:-

a) Starting

the engine.

b) Shifting

the gears.

c) Idling the engine.

clutch Assembly

1.

Functions of a clutch

·

To permit

engagement or disengagement of a gear when the vehicle is stationary and the

engine is running.

·

To transmit the

engine power to the road wheels smoothly without shock to the transmission

system while setting the wheel in motion.

·

To permit the engaging of gears when the

vehicle is in motion without damaging the gear wheels.

2.

Principle of Operation of a Clutch:-

The clutch principle is based

on friction. When two friction surfaces are brought in contact with each other

and pressed they are united due to friction between them. If one is revolved

the other will also revolve. The friction between the two surfaces depends

upon-

i.

Area of the

surface.

ii.

Pressure applied

upon them.

iii.

Coefficient of

friction of the surface materials

iv.

Here, one surface

is considered as driving member and the other as driven member.

The driving member of a clutch

is the flywheel mounted on the crankshaft, the driven member is the pressure

plate mounted on the transmission shaft. Friction surfaces (clutch plates) are

between the two members (driving and driven). On the engagement of the clutch,

the engine is connected to the transmission (gear box) and the power flows from

the engine to the rear wheels through the transmission system. When the clutch

is disengaged by pressing a clutch pedal, the engine is disconnected from the

transmission and consequently the power does not flow to the rear wheels while

the engine is still running.

Principle of

Friction Clutch

1.

Friction clutch

In these types of clutches, friction

force is used to engage and disengage the clutch. A friction plate is inserted

between the driving member and the driven member of clutch. When the driver

releases the clutch pedal, the driven member and driving member of clutch,

comes in contact with each other. A friction force works between these two

parts. So when the driving member revolves, it makes revolve the driven member

of clutch and the clutch is in engage position.

5.1.) Single plate clutch:

In

the single plate clutch a flywheel is fixed to the engine shaft and a pressure

plate is attached to the gear box shaft. This pressure plate is free to move on

the spindle of the shaft. A friction plate is situated between the flywheel and

pressure plate. Some springs are inserted into compressed position between

these plates. When the clutch pedal releases then the pressure plate exerts a

force on the friction plate due to spring action. So clutch is in engage

position. When the driver pushes the clutch pedal it due to mechanism it serves

as the disengagement of clutch.

5.2 Working of single

Plate clutch

A

single plate friction clutch consisting of a clutch disk between the flywheel

and a pressure plate. Both the pressure plate and the flywheel rotate with the

engine crankshaft or the driving shaft. Both sides of clutch disc are faced

with friction material.

·

The

clutch disc is mounted on the hub which is free to move axially along the

splines of the driven shaft but not turntable towards the transmission input shaft.

·

The pressure plate pushes the clutch plate

towards the flywheel by a set of strong springs which are arranged radially

inside the body.

·

The three levers (also known as release levers

or fingers) are carried on pivots suspended from the case of the body.

·

These

are arranged in such a manner so that the pressure plate moves away from the

flywheel by the inward movement of a thrust bearing.

·

The

bearing is mounted upon a forked shaft and moves forward when the clutch pedal

is pressed.

Single Plate Clutch

Parts of single plate clutch

Single Plate Clutch

Advantages & Disadvantages

5.3 Advantages:

·

Simple

and inexpensive and need little maintenance.

·

Gear

changing is easier than the cone clutch because the pedal movement is less.

·

It

is more reliable because it does not suffer from disadvantages of binding of

cone.

5.4 Disadvantages:

·

The

springs have to be more stiff hence greater force required to disengage.

5.5 Single Plate Clutch

Applications

·

Single

plate clutches are used where large radial space is available such as: trucks, buses,

cars etc.

·

As

sufficient surface area is available for the heat dissipation in such clutches,

no cooling oil is required. Therefore, single plate clutches are dry type.

5.6 Design details of

single plate clutch

R2

= inner radius of friction surface.

R1= outer radius of friction surface.

P= intensity of pressure normal to friction surface.

Consider a different element at radius R & of width

dr. Then axial load on the differential element is.

dW= p x dA

Ø

Total

axial load on the clutch.

R2

W= ʃ pr x dr equation-1

ʃ pr x dr equation-1

R1

And total torque transmitted.

R2

Pr = constant (uniform rate of wear)

i)

Uniform pressure intensity

From equation-2

T= μ /3 (R13- R23) multiply (R12- R22)

to numerator & denominator

= [2/3 μ (R13- R23)/ (R12- R22)]  p (R12-

R22)

p (R12-

R22)

=2/3 μ W (R13- R23)/ (R12- R22) [W=

= μ W R [R=2/3(R13- R23)/ (R12- R22)]

ii)

Uniform rate of wear

W=2

from equation-1

from equation-1

T= μ /3 (R12- R22) from equation-2

T= μ/2 (R1- R2) [ r (R1- R2)]

r (R1- R2)]

T= μ W [(R1- R2)/2] effective mean

radius R= (R1- R2)/2

T= μ W R equation-3

Now in an actual single plate clutch,

there are 2 pairs of friction surfaces

Equation 3 modified as

T= 2μ W R

Ø Design & Calculation of single plate clutch

P1 – Friction pad inner diameter

P2 – Friction pad thickness

P3 – Friction facing thickness

Ri – Inner radius of clutch disc in meters

Ro – Outer radius of the clutch disc in meters

N – Speed of engine in rpm = 3750 rpm

ωr – angular velocity in rad/s

P max – clamping pressure in MPa

Ø Mathematical Calculations

The material considered for the friction pad is Kevlar 49

Aramid. Uniform Wear Theory is considered for calculations, and accordingly,

the intensity of the pressure is inversely proportional to the radius of

friction plate.

𝑅 =𝑅𝑖+𝑅𝑜 /2= 0.1𝑚

In general, the frictional torque acting on the clutch

plate is given by

𝑇 = 𝑁 ×μ ×W ×R

In general, the frictional torque acting on the clutch

plate is given by 𝑊 = 3000𝑁

𝑃 ×𝑟 = 𝐶 (𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡)

Axial force on the clutch pad,

𝑊 = 2𝜋×𝐶 × (𝑅𝑜 −𝑅𝑖)

𝐶 = 0.0119𝑁𝑚

The maximum pressure occurs at the inner radius and the

minimum pressure at the outer radius.

In general, the frictional torque acting on the clutch plate

is given by

𝑃𝑚𝑖𝑛 =𝐶 𝑅𝑜= 0.0994 𝑀𝑝𝑎

𝑃𝑚𝑎𝑥 =𝐶 𝑅𝑖 = 0.1492 𝑀𝑝𝑎

Here, we consider the maximum pressure value obtained in

the Finite Element Analysis of the clutch plate.

Ø Thermal Analysis

T – Temperature of the disc in Celsius

T1 – Limiting temperature of the material in Celsius =

150ºC

µ - Coefficient of friction of the material = 0.4

k – Thermal conductivity of the material in Watts per

meter Kelvin

h – Heat transfer coefficient of the material.in Watts

per sq. meters per Kelvin.

q – Heat energy generated in watts

qf – heat flux in W/m2

t – Slip time in seconds = 0.5s

A – Area of a friction pad = 0.000931m2

4.2 Mathematical Calculations

𝜔𝑟 =2×𝜋×𝑁/ 60= 392.6𝑟𝑎𝑑/𝑠

𝑞 = 𝜇 ×𝑃𝑚𝑎𝑥 ×𝜔𝑟 = 23.4375 𝑊

𝑞𝑓 =𝑞 𝐴

= 25155𝑊/𝑚2

6.) Multi

plate clutch:

A multi-plate clutch is a type

of clutch in which the multiple clutch plates are used to make frictional

contact with the flywheel of the engine in order to transmit power between the

engine shaft and the transmission shaft of an automobile vehicle. A multi-plate

clutch is used in automobiles and in machinery where high torque output is

required. In bikes and scooter multi-plate clutch is used due to the limitation

of compact gearbox used in bikes and scooter.

Multi plate clutch

6.1 Multi Plate Clutch Working

Multiplate plate clutch working

·

During

clutch engagement, spring pressure forces the pressure plate towards engine

flywheel. This causes the friction plates and the steel driven plates to be

held together.

·

Friction

locks them together tightly. Then the clutch basket, drive plates, driven

plates, clutch hub and the gearbox input shaft all spin together as one unit.

·

Now

power flows from the clutch basket through the plates to the inner clutch hub

and into the main shaft of the transmission.

·

The

clutch gets released or disengaged when the clutch pedal is pressed. This

causes the clutch pressure plate to be moved away from the drive and driven plates,

overcoming the clutch spring force.

·

This movement of the pressure plate, relieves

the spring pressure holding the drive and driven plates together. Then the

plates float away from each other and slip axially.

·

Thus,

the clutch shaft speed reduces slowly. Finally, the clutch shaft stops

rotating. Power is no longer transferred into the transmission gearbox.

6.2 Multi Plate Clutch Advantages & Disadvantages

Advantages:

·

Increase

the amount of torque to be transmitted.

·

Decrease

the pedal effort to operate the clutch.

·

Decrease

the weight of the clutch.

·

Decrease

the moment of inertia of the clutch.

·

Increase

in better acceleration.

Disadvantages:

·

Heavy.

·

Too

expensive.

6.3 Multi Plate Clutch

Applications

·

Multi

plate clutches are wet type.

·

Multi

plate clutches are used where compact construction is required, e.g. scooters

and motorcycles.

6.4 Design details of

Multiplate clutch

If n= total number of friction

plate in the Multiplate clutch, then, number of pairs of contact surfaces =

(n-1).

T=

(n-1) μ W R equation-1

Accordingly,

i.)

For

uniform pressure intensity,

T = (n-1) 2/3 μ W (R13- R23)/ (R12- R22) equation-2

ii.)

For

uniform rate of wear,

T= (n-1) μ W [(R1+ R2)/2] equation-3

6. Cone clutch

A simple cone clutch is shown in figure. Cone clutch

consists of an inner cup attached to driving shaft and follower cone. Follower

cone is movable; it can axially slide over the driven member. The inner side of

the driver cup exactly fits the outer surface of the cone. The slope of the

cone is made small, that help to give higher normal forces. The recommended

angle of slope is between 8-15 degree. According to the allowable normal

pressure and coefficient of friction required the contact face of the driven

member is lined with material like leather, asbestos, wood, etc. The clutch

engaged by bringing two cone surfaces together in contact. A spring is provided

on the drive shaft to hold the face of clutch in touch by producing required

axial force. A forked lever is used to disengagement of the clutch.

6.5

Advantages of Cone Clutch:

1.

Small axial force is required to keep the

clutch engaged.

2.

Simple design.

3.

For a given dimension, the torque transmitted

by cone clutch is higher than that of a single plate clutch.

6.6 Disadvantages of Cone Clutch:

1.

One pair of friction surface only.

2.

The tendency to grab.

3.

The small cone angle causes some reluctance in

disengagement.

6.7 Design of cone clutch

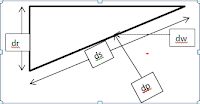

Consider a different element at radius r & of width ds as shown. Then area of this differential element dA is given by.

Where p is the intensity of pressure normal to friction

surfaces

Axial load on the differential element is.

dW =dP sinϴ = 2 dr sinϴ/sinϴ =

dr sinϴ/sinϴ = equation-1

equation-1

Total Axial load on the clutch

r2

W=ʃ dW from

equation-1

r1

r2

W= ʃ pr x dr equation-2

ʃ pr x dr equation-2

r1

And total torque transmitted.

r2 r2

T=ʃ μ  .r =

.r = μ

μ /sinϴ [T=W x dp] equation-3

/sinϴ [T=W x dp] equation-3

/sinϴ [T=W x dp] equation-3

/sinϴ [T=W x dp] equation-3

r1 r1

r2

T= μ

μ equation-4

equation-4

equation-4

equation-4

1.

Uniform

pressure intensity P=constant. This condition is experienced when the two

friction surfaces are perfectly contacting each other.

1.

Uniform

pressure intensity

Equation 3 can be written as

r2 r2

W= ʃ r dr =

2

ʃ r dr =

2 [r/2]

equation-2

[r/2]

equation-2

r1

r1

=  (r22-

r12)

equation-5

(r22-

r12)

equation-5

This is independent of the cone angle.

From equation-4

r2

T= μ

μ from equation-4

from equation-4

from equation-4

from equation-4

r1

T= μ

μ  (r23- r13) equation-4

(r23- r13) equation-4

T= μ

μ  (r23- r13)/ (r22-

r12)] x [

(r23- r13)/ (r22-

r12)] x [  (r22-

r12)] substituting

from equation-5

(r22-

r12)] substituting

from equation-5

T=μWR R=  (r23- r13)/ (r22-

r12)]

(r23- r13)/ (r22-

r12)]

i.)

Uniform rate of wear

r2

W=2 ∫dr =2

∫dr =2 (r2-r1) equqtion-5 from equation-1

(r2-r1) equqtion-5 from equation-1

r1

r2

T= μ

μ

r1

=  μ

μ (r22-

r12)] equation-4

(r22-

r12)] equation-4

= [2 (r2 –r1)]

[μ/2sinϴ (r2-r1)]

(r2 –r1)]

[μ/2sinϴ (r2-r1)]

T= μ W/2sinϴ [(r2+r1)] substituting from equation-5

T= μ W R R= (r2+r1)/2sinϴ R=Effective mean radius

Application of Cone Clutch:

Cone Clutches are used in specialist

transmissions in racing, rallying, or in extreme off-road or other industrial

applications.

Ø Formulae

of single , multi & cone clutch

Sr.no

|

Type of clutch

|

Uniform pressure Theory

|

Uniform wear theory

|

1

|

Single plate clutch

|

T= 2/3 μ W (R13- R23)/ (R12- R22)

|

T=1/2 μ W [(R1+R2)]

|

2

|

Multi plate clutch

|

T= n 2/3 μ W (R13- R23)/ (R12- R22)

|

T=n 1/2 μ W [(R1+R2)]

|

3

|

Cone clutch

|

T= 2/3 μ W (R13-

R23)/ (R12- R22) x

cosecα

|

T= 1/2 μ W [(R1+R2)]cosecα

|

Power transmission by single plate clutch is

given by.

P = ω T

P=2 NT/60 watt

NT/60 watt

Where N= speed of driving shaft.

· Centrifugal clutch:

Principle:

All friction clutch

works on same principle. In centrifugal clutch the initial force which are used

to engage the clutch is achieve by centrifugal action or centrifugal force.

This centrifugal force automatically engage the clutch at a predefine speed and

disengage it when the engine slow down below a limit.

7.1

Construction

Centrifugal

clutch

Spider or Guide:

Spider or guide is works as one of the

pressure plate of simple clutch. It is connected to the driving shaft of

engine. It is called guide way because it hold the shoe and guide its movement.

The initial position of shoe in the guide is controlled by the springs.

Drum:

Drum act like the pressure plate of a simple

clutch. It is connected with the driven member and rotates with it. Drum does

not directly connect with the guide or shoe.

Shoe:

Shoe

is major part of centrifugal clutch. It acts like engaging member of guide and

drum during running condition. When the driving shaft rotates, it makes rotate

the shoe which is free to move in guide. Due to rotation a centrifugal action

works on it which forces it outward and connects with drum.

Springs:

Springs

are controlling element of this type of clutch. Each shoe require one spring.

The shoe is connected with the guide through these springs. It holds the shoe

at its initial position unlit driving member achieves the required speed at

which the centrifugal force can overcome spring force. If we want to change the

engaging speed of the clutch, we simply change these springs with higher spring.

Friction Lining:

The

outer face of the shoe which is going to connect with drum is equipped with

friction lining. These lining play the same role which friction plate play in

simple clutch. It is used to transmit torque from driving member to driven

member and also avoid direct contact of shoe through drum which reduces wear

and tear of shoe.

7.2 Working:

·

At the initial condition when the engine

is off the shoe are not connected with the drum.

·

As the engine start, the Spider or Guide

attached with engine shaft start to rotate.

·

The shoe connected with the spider also

rotate with it and felt some centrifugal action.

·

This centrifugal force makes shoe to

slide in the direction of circumference.

·

At low speed, the centrifugal force is

too low to overcome the spring force which tends to bind the shoe inside the

guide.

·

As the speed increases the shoe move

outside and make a contact with drum. The friction lining between shoe and drum

start to transfer torque from engine to drum.

·

Now the drum start to rotate and as the

speed of engine increase, it will increase the centrifugal force and also the

efficiency of torque transmission through centrifugal action.

·

When the engine speed decrease, will

decrease the centrifugal action which remove the contact of drum and shoe and

disengage the clutch.

·

Thus this is an automatically speed

operated clutch. The operating speed of clutch can be maintained by replacing spring.

7.3 Advantages:

·

It is low in price.

·

Easy to operate.

·

It doesn’t require any separate control

mechanism like clutch pedal etc.

·

The engaging speed can be preciously

controlled by selecting springs.

·

It is used for automating transmission

in which the driver first select gear and then press the accelerator pedal.

·

It requires less maintenance.

7.4 Disadvantages:

·

Power transmission is limited due to

slippage.

·

It cannot used to transmit high amount

of torque.

·

The power transmission or speed

regulation is totally depended on controlling speed.

·

Overheating problem due to quick

engagement during running condition.

7.5 Application:

·

It is used in chain saw, lawn mower etc.

·

It is used in textile industries.

7.6 Design of centrifugal clutch

In the designing of centrifugal clutch it is

required to determine the weight of the shoe,size of the shoe & dimensions

of the sprig. The following procedure may be adopted or the design of a

centrifugal clutch.

7.2

Mass

of the shoes

Consider one shoe of a centrifugal

clutch

Let m= mass of each shoe

N= no of shoes

r= distance 0f centre of gravity of the shoe from the centre of the

spider.

R= inside radius of the pulley

rim

N= running speed of the pulley in r.p.m

ω= angular running speed of the pulley in

rad/sec =2  N/60 rad/s

N/60 rad/s

ω1=angular speed at which

the engagement begins to take place and

μ = coefficient

of friction between the shoe & rim.

We know that the centrifugal force acting

on each shoe at the running speed.

Pc = mrω2

Since the speed at

which the engagement begins to take place is generally taken as 3/4th

of the running speed therefore the inward force on each shoe exerted by the

spring is given by.

Ps =m ω12 r = m(3/4 ω)2 r

=( 9/16) mω2 r

Net outward radial Force (i.e.

centrifugal force with which the shoe presses against the rim at the running

speed

= Pc- Ps = mrω2 - ( 9/16) mω2

r = 7/16 m r ω2

And the frictional force acting

tangentially on each shoe

F= μ (Pc- Ps)

Frictional torque acting on each shoe

F x R = μ (Pc- Ps) x R

And Total frictional torque

transmitted,

T= μ (Pc- Ps) x R x n

T= n F R [F=μ (Pc-

Ps) ]

From this expression the mass of the

shoes (m) may be evaluated.

·

Size of the shoes

Let l = contact

length of the shoes

b= width

of the shoes

R = contact

radius of the shoes. It is same as the inside radius off the rim of the

pulley.

ϴ= angle subtended by the shoe at the

centre of the spider in radians and

P =

intensity of pressure exerted on the shoe. In order to ensure reasonable

life, it may be taken as 0.1 N/mm2

We know that ϴ= I/R or I= ϴ R =

Area of contact of the shoe

= l. b

And the force with which the shoe

presses against the rim

= A x p = l.b.p

Since the force with which the shoe

presses against the rim at the running speed is (Pc- Ps) therefore

l.b.p =Pc - Ps

From this expression the width of

shoe (b) may be obtained.

·

Dimensions of the spring

We have discussed above that

the load on the spring is given by

Ps = (9/16) x mrω2

The dimensions of the spring may be

obtained as usual.

|

||

8 Semi-centrifugal clutch

8.1

Construction

details of semi centrifugal clutch:

|

||

·

Three hinged and

weighted levers and three clutch Springs alternately arranged at equal

space on the Pressure plate (only one lever and clutch spring shown in

figure)

·

Fly wheel is

fitted to engine crank shaft

·

Clutch plate is

mounted on the splines of the clutch shaft

·

Pressure plate is

freely supported on clutch shaft

Semi-centrifugal clutch

8.2 Working of Semi centrifugal clutch

Clutch engaged

·

Clutch

springs exerts pressure on pressure plate at low engine speeds

·

At high

speeds the centrifugal force developed by rotation of weighted levers

Exerts pressure on pressure plate

·

Pressure

plate applies pressure on clutch plate

·

Clutch

plate firmly rotates in between fly wheel and pressure plate

·

Clutch

shaft rotates along with clutch plate

Clutch disengage

·

As Driver

presses the clutch pedal, pressure plate moves back against the force of

The springs

·

Clutch

plate also moves back on splines of clutch shaft

·

Clutch

plate speed reduces slowly and finally stops

8.3 Advantages

of semi centrifugal clutch:

·

Less stiff clutch

springs are used as they operate only at low speeds

·

Driver will not

get strained in operating the clutch

Disadvantages of centrifugal clutch

·

automatically

disengaging at low engine speeds

·

Only at high

speeds, centrifugal force is sufficient to keep the clutch in engaged position

Used in

·

Vauxhall car

(foreign car)

8 Clutch Operating Linkage

The clutch unit is a rigid

part of the flywheel and hence the crankshaft assembly. It is therefore

subjected to the engine and transmission vibrations such as rocking, shaking

and pitching. The clutch foot-pedal assembly, on the other hand, is attached to

the body structure. As a result, this may be subjected to slight bump and

rebound movements of the body. For smooth operation of the clutch without any

jerks, some sort of flexible linkage system must be incorporated, which does

not interfere with the clutch adjustment, is compact, needs very little

maintenance, has a long working life, is simple, and is reasonably cheap. The

three basic methods of transmitting movement and force to the clutch from the

foot pedal are

9.1 Mechanical Operation.

·

Rod-operated

Linkage

As the clutch pedal is

pressed, it pivots about the mounting bracket and the withdrawal rod pulls back

or forwards according to the arrangement. Consequently the withdrawal lever

rotates the fork-arm about the cross-shaft and pushes the thrust-bearing saddle

against the clutch release-plate. This causes the movement of the release

levers towards the flywheel, so that they pivot about the eyebolt pins,

withdrawing the pressure-plate from the driven-plate thereby interrupting the

drive.

9.2

Cable-operated Linkage

Cable linkage is a popular

and effective method of transferring movement from the pedal to the clutch. The

cable assembly uses an inner multi-strand steel-wire core and an outer cable

sheath of a spiral wound flexible sleeve normally with nylon end-pieces. This

plastic sleeve provides very good rubbing wear properties without requiring in

general any lubrication. Also the inside of the sleeve may be lined with

anti-friction material such as Polytetra fluorethylene (PTFE) plastic to

minimise any slip-stick friction.

9.2 Hydraulically-operated Linkage

A more

convenient way to transmit force and movement is by hydraulic linkage in which

the fluid is forced through a flexible plastic pipeline, spun between the

foot-pedal and the clutch bell-housing. A master-cylinder, mounted on the

bulkhead and a push-rod joining the clutch-pedal to the sliding piston,

provides the control of the clutch action. A slave cylinder unit containing the

piston is installed on an extension formed on the bell-housing flange. The

slave piston relays the slightest movement to the fork-lever through the slave

pushrod. The thrust bearing assembly is fixed to one end of the fork lever, and

a spherical pivot is installed slightly in from this end.

The master-cylinder piston pushes a

continuous column of fluid through the pipeline when the clutch pedal is

pressed down. This causes the displacement of an equal volume of fluid into the

Master cylinder slave cylinder

Driven-plate wear, in this system, is compensated by the slave return-spring and piston automatically moves to take up the increased fork-lever tilt. The hydraulic actuating mechanisms are independent of frictional wear unlike cables due to application of large leverage. This system is particularly suitable for heavy-duty vehicles such as on large trucks.

Driven-plate wear, in this system, is compensated by the slave return-spring and piston automatically moves to take up the increased fork-lever tilt. The hydraulic actuating mechanisms are independent of frictional wear unlike cables due to application of large leverage. This system is particularly suitable for heavy-duty vehicles such as on large trucks.

9.4 Vacuum-operated Clutch

In this type of

clutch, engine intake manifold vacuum is used for disengaging the clutch. It

uses a vacuum reservoir connected to the intake manifold through a non-return

valve. It has a vacuum cylinder and piston, the rod side of the piston is

opened to the atmosphere. The solenoid valve is operated when the switch is

closed so that the circuit is complete. The switch is mounted on the gear lever

so that when the gear lever is operated to change the gear, the switch is also

closed.

Vacuum clutch

In the normal

position the valve rod is in the bottom position of the valve (shown dotted in

and the switch is open. At this stage, the pressure on both sides of the piston

in the vacuum cylinder is atmospheric. When the switch is closed due to the

operation of gear change lever, the solenoid coil is energized and the valve

rod is pulled up. This action opens the passage between the reservoir and the

vacuum cylinder, so that a pressure differential acts on the piston of the

vacuum cylinder. As a consequence the piston moves in the forward direction,

causing the operation of linkage to disengage the clutch.

9

Electromagnetic Clutch

Construction

Rotor:

Rotor

is a major part of this clutch witch is connected directly to the driving shaft

or engine shaft. It continuously rotates along with the driving shaft.

Winding or Coil:

Winding

coil is situated behind the rotor and remains in stationary position during

clutch working. It is shown in figure. A high voltage DC supply is connected

with this winding which transfer a high voltage current into this winding and

convert it into electromagnet.

Armature:

Armature

is situated at front of the rotor. It is connected to the hub or pressure

plated with the help or rivet or bolted joint.

Hub:

Hub

or pressure plate is bolted with the gear shaft or driven shaft and rotates

with it. It is situated after the armature.

Friction Plate:

Friction

plate is inserted between armature and rotor according to the requirement.

Supply unit:

Supply

unit consist clutch switch, battery, wire etc.

10.1 Working:

·

The

electromagnetic clutch working can be summarized into following points.

·

In the initial

condition the clutch is in disengage position. There is an air gap between

rotor and hub.

·

First

the engine starts which makes rotate the rotor connected with the engine shaft.

·

A DC

battery supplies DC current into the clutch winding.

·

This

high voltage DC current converts this winding into an electromagnet which

attract armature towards it.

·

This

armature force friction plate towards the rotor and make rotate the hub.

·

Thus

the hub rotate and the rotor transmit 100% torque during engage position.

·

When the

clutch switch / pedal is pressed, the battery stops the supply in winding which

remove the electromagnetic force, thus the clutch is in disengage position.

10.2 Advantages:

·

No

linkage is required to operate the clutch. So it can be installed any remote

location.

·

It can

be used to achieve automatic transmission.

·

Easy to

operate.

·

Less

wear and tear at contact point.

10.3Disadvantages:

·

This

clutch operating temperature is limited by the temperature rating of the

insulating material.

·

High

initial Cost.

11. Cable type clutch linkage

A

cable-type clutch linkage is simple, lightweight and is the most common linkage

on newer cars today. Normally, a cable connects the pivot of the clutch pedal

directly to the release fork. This simple design is flexible, compact, and

eliminates nearly the entire wearing pivot points found in a shaft and lever

linkage. There is one downside to this type of setup: cables will gradually

stretch and can break due to excessive wear and electrolysis.

On a typical installation,

one end of the cable is connected to the clutch pedal and a spring is attached

to the pedal assembly to keep the pedal in the "up" position. The

other end of the cable is connected to the clutch release fork with a fitting

that allows for free-play adjustments. When the clutch pedal is depressed, the

cable pulls the clutch fork, causing the release bearing to move forward

against the pressure plate.

Commonly found in

mid- and rear-engine vehicles, a hydraulic clutch linkage is basically a mini

hydraulic brake system. A master cylinder is attached to the clutch pedal by an

actuator rod, and the slave cylinder is connected to the master cylinder by

high-pressure tubing. The slave cylinder is normally attached to a bracket next

to the bell housing, so that it can move the clutch release fork directly.

Cable type clutch linkage

11.1The advantages of cable clutch

·

Because

the cable clutch system has so few pivot points, there are fewer parts that

will sustain damage through ordinary wear and tear. There’s a lot going on

mechanically when it comes to getting your vehicle in and out of gear and the

simpler the system, the lower the likelihood of developing problems.

11.2 The disadvantages of cable clutch

·

The

only downside to a cable clutch is that if you own your car for a long time,

the cables will eventually wear and stretch, and could even break. If the cable

wears or stretches, you may find it difficult to put your car in gear. If it

breaks, you won’t be able to shift at all.

12. Wet Clutches

It is in most cases multi plates clutch. It

has 5-10 metal disks connected to "bell" (engine side) by splines on

the outer side, and similar number of friction material covered metal disks

connected to "outgoing shaft" (by splines in centre of disks). They

are mounted in enclosed housing, filled with ATF oil, and rotate with engine.

From "shaft" side is mounted hydraulic cylinder, which press plate’s

together when clutch drive. It rotates together with clutch bell, and has oil

pressure feeding through shaft. It is simple explanation of its construction.

12.1Wet Clutch (Multi-plate Clutch)

Working

The clutch has 2 modes of operation-

engagement and disengagement. During the engagement mode, the plates are

squeezed together and the transmission fluid present between the plates is

pushed out. Torque is then transmitted through the clutch and to the

corresponding gear set. The engagement process takes place in three stages.

·

Hydrodynamic

stage

·

Contact

stage

·

Locked up stage

·

During

the hydrodynamic stage, the plates are separated from each other and are filled

with a film of fluid. As a result of which torque is not developed through

frictional contact but in contrast it is developed due to the viscous torque

transfer through the automotive transmission fluid (ATF). The plates now start

moving closer to each other and the fluid film begins to shrink.

·

The

contact stage is said to occur when the plates are squeezed further towards

each other. Few contact points are said to be formed and these are known as

asperity points. Torque is slowly transferred through these asperity points

which increase gradually and hydrodynamic torque consequently begins to

decrease. There is a slip or relative velocity between the plates at this stage

due to which there is an increase in the temperature of the plates.

·

The

final stage is the locked up stage where in the torque is entirely transmitted

through frictional contact only. The steel and friction plates are completely

in contact with each other and hence rotate at the same speed. The transmission

fluid in between the plates is completely squeezed out. The presence of grooves

in the plates plays a major role in guiding the fluid and hence plays a role in

the torque capacity and heat flow. The disengagement mode also called as the

open clutch condition is when the friction disc and the steel plate are

separated from each other and are rotating at different speeds. Hence a

relative velocity exists between the two. A hydrodynamic torque is developed

during such a situation. This is caused because of the shearing effects of the

viscous fluid and the torque developed is referred to as drag torque. The drag

torque mainly depends on the viscosity of the fluid and also depends on the

presence of air bubbles trapped between the plates.

12.2

Drag torque physics of wet clutch

Two

discs at certain distance apart from each other are considered with a fluid

filled between them. One of the discs is stationary while the other is moving.

The fluid present within them will offer an internal resistance to the motion

of the plate in the form of a shearing force. This shearing force due to the

viscous effect of the fluid is termed as drag torque and is also known as drag

loss.

The

drag torque leads to a loss in power in the transmission. For an automatic

transmission, it contributes as much as 20% to the entire transmission losses. The

drag torque in a clutch is said to be influenced by the following parameters.

·

Drag

torque increases with an increase in the number of discs used in a clutch pack

·

Drag torque decreases with an increase in

clearance between two consecutive discs.

·

Drag

torque decreases with a decrease in lubrication flow rate.

·

Drag

Torque increases with a decrease in temperature. Temperature plays a major role

and with a change in temperature, the viscosity and density of the fluid also

changes.

·

Drag torque increases with an increase in the

radius of the discs.

Typical drag torque behaviour can be as shown as follows.

Drag torque in a wet clutch is plotted

against the relative speed of the plates. It is divided into three regions-

region I, region II and region III.

Initially, there is a linear increase in drag torque with relative speed

up to a particular speed (critical speed). This is because drag toque is

proportional to the relative speed and there is a full film of oil that exists

between the discs. This corresponds to the region I. The region II can be seen

as region of decreasing drag torque and as the speed increased the drag torque

decreased further. This is attributed to the fact that earlier in region I,

centrifugal effect was quite low and surface tension forces predominated. The

surface tension forces were responsible in keeping full film of oil between the

plates as much as possible. But as the speed increased, the centrifugal forces

dominated and as a result of which small air pockets were formed near the outer

diameter of the discs. These air pockets gradually became bigger as the

relative speed increased. This consequently led to the oil film diminishing and

resulted in a decrease in drag torque.

Finally region III causes an increase in drag torque with

increase in relative speed. This is explained by the fact that fluid forms a

mist between the clutch plates. This was seen in many visual experiments.

12.3 Wet Clutch-

Advantages:

·

Lesser heat will

be generated.

·

Friction produced

will be lesser.

·

Minimal slipping

during shifts.

·

High

torque capacity

·

Low

weight, easy packaging

·

No

noise or vibrations (Good NVH characteristics)

·

Long

life

·

High

energy density

·

Low drag Torque to reduce fuel cost

Disadvantages:

·

Harder to

maintain.

·

Difficult to

clean.

12.4

Nissans Intelligent dual clutch control technology

Ø Dual

Clutch Technology Functionality hybrids.

In

a hybrid system, the motor supports the engine, improving driving performance

and fuel consumption by regenerating with the motor and storing energy in the

battery, using this to drive like an EV and for accelerating.

The one-motor two-clutch hybrid system can separate the engine from the drive train as necessary. It can utilize the engine and motor as power sources, from running just on the motor to using both motor and engine for full acceleration, achieving a more efficient drive as per the situation. During regeneration and electric-mode driving, the engine is completely disconnected from the drive-train, resulting in zero loss from engine friction.

The one-motor two-clutch hybrid system can separate the engine from the drive train as necessary. It can utilize the engine and motor as power sources, from running just on the motor to using both motor and engine for full acceleration, achieving a more efficient drive as per the situation. During regeneration and electric-mode driving, the engine is completely disconnected from the drive-train, resulting in zero loss from engine friction.

System of 2 Clutch hybrid cars

·

Nissan

replaced an existing 7-speed automatic transmission’s torque converter with a

motor and two clutches in a compact configuration. Using a one-motor system to

drive the wheels and regenerate electricity allows for a reduction in the

number of parts and a lighter weight.

·

The

two clutches transfer energy mechanically to the engine and motor. While being

efficient and with little energy loss compared to a normal torque converter,

the system also has intuitive and responsive acceleration. Through integrated

control of this system and transmission using high-level control technology it

achieves a drive that responds to a range of driving conditions.

·

The hybrid car lithium-ion battery can

discharge high currents in a short time. In this way, the proportion of running

the motor increases, and it is possible to recover braking energy frequently.

Being able to use electricity effectively means the consumption of gasoline

fuel decreases and contributes accordingly to better mileage.

13. Difference between Dry & Wet

clutch

Dry clutch

|

Wet clutch

|

A dry clutch is a clutch which does not have oil present between the

clutch plates

|

Physical oil is

present between the plates of the clutch

|

The sound in dry clutch is more as compared to wet clutch and goes on

increasing as the clutch goes on wearing out.

|

The sound level is net clutch is less as compared to dry clutch or it

is taken up by the oil present between the plates

|

Wear and tear is more in dry clutch

|

Wear and tear is less in wet clutch

|

Maintenance cost is high

|

Maintenance cost is low

|

The life is less as compared to wet clutch

|

The life is more as compared to wet clutch

|

The dust which is collected by wear and tear of the plates is in the

cover of the clutch casing.

|

The dust is removed by the oil filter present in the clutch casing.

|

13. Main Parts of clutch:-

Main

parts of clutch

The clutch assembly consists of many small parts

but following are the major parts

1. Flywheel – The flywheel,

mounted on the crankshaft, keeps on running as long as the engine keeps

running. The flywheel is equipped with friction surface OR a friction disc is bolted to outer side of

flywheel.

Flywheel

2. Friction discs – Single OR

multiple (as per requirement) discs lined with friction material having high

coefficient of friction are mounted on the drive shaft.

3. Pressure plate – Another friction disc is bolted to pressure plate. The pressure plate is mounted on the splined hub.

3. Pressure plate – Another friction disc is bolted to pressure plate. The pressure plate is mounted on the splined hub.

pressure plate

4. Spring & release

levers – The spring used are diaphragm springs which moves friction

disc back & forth. The spring is retracted with the help of levers.

5. Piolet bearing:-A pilot bearing supports the

engine side of the input shaft. The pilot bearing used on Toyota vehicles is a

ball bearing located in a bore in the end of the crankshaft. The pilot bearing

only turns when the clutch is disengaged.

6. Clutch cover Assembly: - The

clutch cover assembly is bolted to the flywheel and provides the pressure

needed to hold the clutch disc to the flywheel for proper power transmission.

It is important that the assembly be well balanced and able to radiate the heat

generated when the clutch disc is engaged.

Toyota uses two types of clutch

cover assemblies:

• Diaphragm spring

• Diaphragm Spring Turnover (DST)

clutch cover

13.1 Diaphragm

Spring Turnover

The Diaphragm Spring

Turnover (DST) type of clutch cover assembly differs from the conventional type

only in construction. The DST cover does not use a separate pivot stud to

connect the diaphragm spring to the cover. The cover is shaped so that the

pivot points are part of the clutch cover. Since the retracting springs have

been eliminated, the strap springs are used to disengage the pressure plate

from the clutch disc. The diaphragm spring fingers are chrome plated in the

area where the release bearing rides to help eliminate wear and noise. With

this design, the clutch cover gives optimum release performance and is

lightweight.

Diaphragm Spring

Turnover

13.2 Self-Centering Release Bearing

A self centering

release bearing is used to prevent noise caused by the release bearing pressing

unevenly on the diaphragm spring. This noise occurs when the centerline between

the crankshaft, clutch cover assembly, transaxle input shaft and release

bearing is not the same. It is used on transaxles because the input shaft does

not fit into a pilot bearing in the crankshaft like a transmission input shaft

does. The transaxle input shaft is supported by bearings in the case. The self

centering release bearing automatically compensates for this by aligning itself

with the centerline of the diaphragm spring. This helps prevent noise

associated with clutch disengagement.

Self-Centering

Release Bearing

The hub of

the self centering release bearing is made of pressed steel. The bearing is not

pressed onto the hub as with the conventional release bearing. A rubber seat,

resin seat, bearing, and wave washer are secured to the hub with a snap ring.

The inner diameter of the release bearing is 1 to 2mm greater than the outer

diameter of the hub. This clearance allows the release bearing to move and self

center to avoid wear.

Self-Centering

Release Bearing

13.3 Requirement

of a good friction lining:

§

High co-efficient of friction.

§

Good wearing properties.

§

Cheap and easy to manufacture.

§

High resistance to heat.

.4

Clutch Friction

Material:

§ Organic

§ Heavy- duty organic

§ Cermaics

§ Kevler

§ Feramic

§ FeramAlloy

Facing

1. Organ

- Organic facings are typically made from phenolic resins, friction modifiers like metallic powder or metal oxides, and compounded rubber. These facings come in two types:

Ø

Molded Facings:-which are very affordable but

lack strength.

Ø

Woven Facings: - which include fiberglass yarn

woven into the material to increase strength.

As

you can see, woven organic facings are much stronger than Molded facings, which

translate to better life and performance.

Woven

organic friction materials are commonly used in OEM applications, as they offer

a good combination of smooth engagement, wear resistance, and strength.

2. Heavy- duty organic

·

Heavy-duty organic clutch facings are similar to

normal organic clutches in terms of engagement smoothness, but with more

temperature resistance and durability.

·

Heavy-duty organic clutch facings feature more

metallic content, which boosts heat resistance and reduces fade.

·

This

gives these clutches resistance to temperatures as high as 700°F, at least for

short periods, as well as increased burst strength.

3. Ceramics

·

Ceramic clutch facings are made from a mixture

of copper, iron, tin bronze, silicon dioxide, and/or graphite. The material is

sintered or brazed onto a backing plate, and then often riveted to the main

clutch plate.

·

Ceramic

clutch facings can withstand considerable heat - they can operate without

fading at temperatures up to 1,000°F. This heat resistance makes them ideal for

racing.

·

Finally, it's important to note that the ratio

of static to dynamic friction is quite high for ceramic clutches. This means

that ceramic clutch engagement can be abrupt.

4. Kevlar

·

Kevlar and Twaron are trademarked names for

para-aramid fibers that are often used to make clutch discs. Kevlar and

Twaron have two key benefits: longevity and smooth engagement.

·

In terms of longevity, Kevlar and Twaron facings last 2-3 times longer than

organic facings, all things being equal. Additionally, these fibers have a low

static-to-dynamic friction coefficient, making them an ideal choice for

applications where smooth engagement is essential (such as off-road driving,

rock crawling, etc.).

·

While

Kevlar facings require higher clamping pressures than most materials – and have

a long break-in period (1,000 miles) - their durability makes them a great

choice for vehicles with stock or slightly modified engines.

5.

Feramic

·

With a high coefficient of friction and a high

static-to-dynamic ratio, most feramic clutch facings are strictly for racing

applications where quick lock-up is most important.

·

Feramic facings are made from a

combination of steel, silicon dioxide, tin bronze, and graphite. Feramic

facings can be full across the face or they can be buttons.

·

A special type of feramic clutch facing - known

as a carbotic facing - is used in truck applications, offering ceramic-like

temperature resistance with smoother engagement.

6. FeramAlloy Facing

·

A newer material, FeramAlloy facings are likely

to replace ceramic facings. FeramAlloy offers similar levels of wear

and temperature resistance compared to ceramics, but with a much better static

to dynamic ratio (and therefore smoother engagement).

·

FeramAlloy facings also have less

"chatter" than ceramic facings.

·

Phoenix Friction is one of the first clutch

manufacturers to begin offering FeramAlloy facings for use on heavy-duty

applications (diesel trucks, commercial trucking, etc.).

13.5 Clutch Friction

material Table

Type

|

μ Range

|

Fade

temp (0F)

|

Best

use

|

Woven

organic

|

0.25-0.3

|

600

|

Daily

driver

|

HD

organic

|

0.25-0.3

|

700

|

Most

street performance, Towing & hauling application

|

Kevlar

|

0.35-0.37

|

500

|

Longevity,

off-roading

|

Carbotic

|

0.45-0.48

|

750

|

Heavy-duty

hauling &towing commercial Trucking

|

Ceramic

|

0.4-0.6

|

1000

|

Racing

|

Feramic

|

0.5-0.55

|

1000

|

Racing/Agriculture

|

FeramAlloy

|

0.4-0.6

|

1000

|

Heavy

duty hauling &Towing, commercial Trucking

|

14. Symptoms of a failing

clutch

- Hard to select gears

- Engine RPM increasing with no increase in vehicle speed

- Burning smell from vehicle

- Clutch pedal not returning

- Unable to depress clutch pedal

- Shudder or vibration when changing gears

14.1

Preliminary clutch inspection

A thorough inspection of all

clutch-operating components should be done before disassembly. The first step

is to inspect mechanical, cable or hydraulic linkages for specified clutch

pedal free-play. Second, since they may affect smooth clutch engagement or

magnify a minor chatter condition, always make sure that the engine and

transmission mounting and torque-absorbing components aren’t oil-saturated,

broken or worn out.

Third, inspect the clutch pedal

lever bushings for excessive wear and inspect the vehicle’s firewall for

excessive distortion when the clutch pedal is depressed. In some cases, a

factory reinforcement kit may be required to restore full travel to the clutch

pedal assembly.

Next, make sure that clutch pedal

travel isn’t limited by an improper pushrod or linkage adjustment or by an

extra-thick floor mat lying under the pedal. Last, inspect hydraulic linkages

for fluid level, fluid condition and external leakage.

14.2 How to Adjust a Clutch

Self-Adjusting Clutch

The self-adjusting clutch is one of the two

types of clutch-adjustment testing methods, and it is the easier of the two.

Step 1 – Lift up the Clutch Pedal

With

your car engine running and your parking brake engaged, slip one foot beneath

the clutch pedal and lift it upward toward you.

Step 2 – Depress the Pedal

Then,

test it by depressing the pedal and putting your car in gear. Make note of the

distance your clutch has to move downward before you can change gears.

Step 3 – Test the Pedal

To give

it a fair test, try putting it into low forward gear, then second forward and

finally third forward. Make note of how much you need to depress the clutch

pedal before it disengages the clutch and allows you to put the car into gear

without grinding any of the gears. Be sure the clutch pedal doesn't come up too

high before it disengages the clutch.

14.3 Manual Clutch Adjustment

Step 1 – Get into the Proper Position

With

your engine turned off and your hand brake engaged, get into a position in the

front seat where you will be able to see behind the car's dashboard on the

driver's side. If necessary, get into position outside the car with the door

open. Lower yourself so that your head is partially under the dashboard.

Step 2 – Push the Clutch Pedal and Locate the Hook

With one

hand, push the clutch pedal toward the floorboard and hold it there. Next,

locate a large hook-like object on the clutch assembly. It should be near the

top of the clutch shaft.

Step 3 – Pull the Hook Upward

As you

continue to put pressure on the clutch pedal, pull up on the hook-like object

until you hear it click once. Then, release your pressure on it.

Step 4 – Test the Clutch

Next,

test the clutch. Climb back onto the seat and start the engine. Keeping one

foot on the brake pedal, push the clutch pedal downward toward the floor with

your foot and adjust your gearshift lever to put your car in gear as you did in

the first test. If the clutch pedal isn't working properly, you can replace it

yourself in a few steps,

too.

14.4 Clutch overhauling

14.5

Clutch removal

- Remove the engine first.

- Mark the flywheel and the clutch cover for later reassembly. Use something like a sharp punch. I've known some people to use paint.

- Remove the bolts securing the clutch cover one turn at a time Do this diagonally opposite one another rather than working directly around the cover. This will help ensure that heavy spring pressure will not warp the clutch cover.

- Once the spring pressure has been relieved, remove each bolt.

- Now remove the clutch.

14.6

Disassembling of Clutch

·

Drain all of the fluids out of your engine and

transmission.

·

Remove the engine and transmission from the car.

·

Remove the bolts holding the transmission to the

engine, and slide the transmission off of the clutch. Some transmissions

require a bit of force.

·

The

exposed surface of the clutch is the pressure plate; you need to remove this to

disassemble the unit. Lock the engine, and then take out all of the bolts on

the edge of the pressure plate.

·

Pull the pressure plate off the flywheel;

normally pressure plates have pins in them, so this might require a little bit

of prying. Once the pressure plate is removed, the clutch disk should simply

fall off.

·

At this movement clutch is disassemble.

14.7 Inspection of clutch components

Experienced technicians know the importance of visually inspecting each clutch component as it is disassembled. This helps determine if a part failed earlier than it should have, and helps locate any condition that needs correcting before the clutch is reassembled.

During disassembly, the flywheel, clutch cover assembly, clutch disc,

release bearing and pilot bearing should be checked to determine if they were

the cause of the failure. During each phase of reassembly, remember to check

for proper clearances and operation. This ensures that any faulty parts or

assemblies can be corrected early in the reassembly process.

14.8 Fly wheel inspection

The flywheel must have a flat surface to prevent chatter,

and the proper surface finish to provide the necessary coefficient of friction.

The wear of the friction surface is usually concave. The new flat clutch disc

will not seat completely against a worn flywheel. This can cause premature

clutch wear, chatter or even clutch disc failure. Grooves, heat checks, and

warping can occur if there is excessive slippage,

The flywheel should be checked for excessive runout if there is

vibration or an odd wear pattern at the hub of the disc or clutch cover release

levers.

Flywheel axial runout:

·

With

the dial indicator mounted with the measuring stem pointing directly toward the

flywheel, adjust the indicator to read zero.

·

While

observing the dial indicator, rotate the flywheel; to eliminate crankshaft end

play, maintain an even pressure during rotation.

·

The

amount of axial runout is indicated by the variation in reading .If the

flywheel is to be removed.

·

Place

index marks at the crankshaft flange for faster alignment during reassembly. Inspect

the starter ring gear teeth. If damaged, replace either the starter ring gear

or flywheel.

14.9 Clutch cover assembly inspection

A used clutch cover assembly should be visually inspected for cover

distortion and friction surface damage. The friction surface of the clutch cover

assembly tends to polish or glaze from normal use. Excessive slippage can cause

grooves, heat checks, and warping.

Set the clutch cover on the flywheel. The flywheel and clutch cover

mounting points should meet evenly and completely. Inspect for gaps, as they

indicate a distorted clutch cover. Additionally, inspect the clutch diaphragm

for wear at the contact surface with the release bearing. Clutch diaphragm wear

occurs at the contact point with the release bearing. Measure the width and

depth of the wear to determine if it is within tolerable limits.

Clutch disc inspection

Always check a

used clutch disc for facing thickness, damper spring condition, hub spline

wear, and warpage or axial runout by measuring the height of the facing surface

above the rivets. The minimum depth should be 0.012 in. (0.3mm). The hub

splines and damper springs should be visually checked for rust and shiny worn

areas, and broken or missing springs.

Disc warpage is checked by completing an axial runout check. The disc is

rotated while watching for wobbling (runout) of the facing surfaces. More than

0.031 in. (0.8mm) is excessive, and the disc should be replaced.

Axial runout check

Disc warpage can also be checked by setting the disc against the

flywheel. The disc facing should make even contact all around the flywheel.

14.10 Release bearing inspection

Release bearings are checked by feeling for roughness and visually

checked for obvious wear. They are normally replaced with the disc and clutch

cover.

On self-adjusting release bearings, also check that the selfcentering

system is not sticking.

14.11 Clutch pedal adjustment

Normal service

for a clutch includes checking the mechanical linkage systems for clutch pedal

height and free play, and checking the hydraulic systems fluid levels.

To check for clutch pedal height, measure the distance from the vehicle

floor (asphalt sheet under the carpet) to the top of the clutch pedal. Refer to

the appropriate repair manual for vehicle specifications.

Clutch height adjustment

If the clutch

pedal requires a height adjustment, it is adjusted using the pedal height

adjust point. Always adjust clutch pedal height before adjusting clutch pedal

free play.

To check and adjust clutch pedal free play, push the clutch pedal

downward by hand until all play is removed and resistance is felt. The distance

from this point to the pedal top position is free play.

Clutch Free play adjustment

Free play

travel that is less than specifications indicates the need for adjustment of

the push rod. Too little free play may result in the clutch master cylinder

compensating port being blocked, preventing the return of fluid. This will

result in difficulty in bleeding the hydraulic circuit and may also cause the

clutch to slip as under hood temperatures cause fluid to expand pushing the

release cylinder piston and release bearing.

Clutch pedal adjustment

To check the clutch release point:

·

Pull

the parking brake lever and install the wheel stopper.

·

Start

and idle the engine.

·

Place

the transmission in high gear and slowly engage the clutch.

·

When

the clutch begins to engage (tachometer speed begins to drop), this is the release

point.

·

Measure

the stroke from the release point to the full stroke end position.

·

Standard

distance: 0.98 in. (25mm) or more (from pedal stroke end position to release

point).

·

If the distance is not as specified, perform

the following checks:

·

Check

pedal height.

·

Check push rod play and pedal free play.

·

Bleed clutch line.

·

Check clutch cover and disc.

Clutch release point

·

Preventive

maintenance :- check pedal free play, check fluid levels, and perform necessary

adjustments to ensure correct system operation.

·

Problem

diagnosis: - determine the cause of a concern in order to specify appropriate

repair procedures.

·

Repair:

- perform appropriate repair or component replacement tasks to attain proper

vehicle operation.

14.12 Clutch slippage

·

This section

describes normal maintenance, adjustments, and diagnostic procedures for common

clutch system concerns.

·

Start

the vehicle and warm up the engine to normal operating temperature, block the

wheels, and apply the parking brake.

·

Shift the transmission into the highest gear

and release the clutch pedal in a smooth, normal motion. If the clutch is

engaging correctly, the engine should stall immediately. A delay in engine

stalling indicates slow engagement and a slipping clutch condition.

14.13 Clutch chatter

·

Clutch

chatter is caused by a clutch that grabs and slips repeatedly, eventually

marring the clutch cover pressure plate and flywheel surfaces. A grabbing or

chattering clutch produces a severe vibration while engaging the clutch and the

vehicle is accelerated from a stop. The vibration can be felt as well as heard

and may transfer to the vehicle body cause secondary noise.

·

Clutch

chatter may be caused by oil or grease on the clutch disc, glazed, loose or

broken disc facings, worn torsion dampers, bent or distorted clutch disc, a

loose clutch cover, missing flywheel dowel pins, or excessive flywheel runout.

Hot spots on the flywheel or pressure plate can cause the clutch disc to be

clamped unevenly resulting in chatter.

·

Influences

outside of the clutch assembly may cause chattering such as; broken engine or

transmission mounts, worn or damaged constant velocity (CV) axle joint or

universal joints. Wear in the joints or loose motor mounts can cause the clutch

to slip after initial engagement while the clutch pedal is released and the

component reaches the end of its play. The abrupt change in rotational speed

feeds back to the clutch causing slippage.

14.14 Clutch drag

Clutch drag is a condition where the clutch does not release completely.

Symptoms can include hard shifting into gear from neutral and gear clash. A clutch

spins down test checks for complete clutch disengagement. The clutch disc,

input shaft and transmission gears should come to a complete stop within a few

seconds after disengaging the clutch.

Checking clutch spin down:

·

Start

the vehicle and warm up the engine and transmission to operating temperature.

·

With

the transmission in neutral and the engine running at idle speed, push in the

clutch pedal, wait nine seconds, and shift the transmission into reverse.

·

Gear

clash or grinding indicates a clutch that hasn’t completely released.

14.15 Clutch judder:

Clutch

judder is most noticeable when setting off from a standstill. It manifests

itself as a strong vibration when you release the clutch to get the car moving

from rest. If you notice clutch judder, it is an indication that the clutch

assembly including the flywheel might need replacement.

14.16 Clutch chatter

Clutch chatter is best described as a stutter or vibration as the clutch

is released. It is most noticeable when starting out from a complete stop.

Clutch chatter is the most difficult clutch problem to diagnose and repair.

Clutch related Chatter problems

Disc

- Clutch Disc related Contamination: Oil on the disc from an engine or transmission leak

- Torsion Spring Escaped: usually caused by “popping” the clutch or attempting to push start the car

Pressure

Plate Distorted

- Pressure Plate Related Warped friction plate: Usually due to excessive heat build-up. Can be caused by excessively slipping the clutch

- Warped Diaphram Spring: Defective part

- Uneven Coil Spring Pressures: Defective part. Very few of this style clutch made today

Release

Bearing

- Release Bearing Related Damaged or Worn Release Bearing: Usually on very high mileage cars, or can result from extended operation with a defective pressure plate

- Grooved release bearing guide

- Worn bearing retainer .

15.

Fluid flywheel

Fluid flywheel

A

liquid coupling is used to transmit engine turning effort (torque) to a clutch

and transmission. The coupling is always a major part of the engine flywheel

assembly. As such it is sometime called a fluid flywheel.

One

of the shells is fixed to the crankshaft of the engine and the other to the

clutch/gearbox shaft. The two shells are mounted very close, with their open

ends facing each other, so that they can be turned independently without touching.

Housing surrounds both units to make a closed assembly. About 80% of the

interior of the assembly is filled with oil.

15.1 Working of fluid flywheel

The driving unit, called impeller, is linked to the engine crankshaft.

When the engine throttle is opened, the oil in the impeller starts moving. Due

to the force of the rotating, trapped oil impinges on the fins of the driven

unit called runner and causes it to move. In this way, the moving liquid

transmits the engine power to the clutch driving plat or to any other unit to

which the runner is attached. This happens without any metal contact.

In the actual units, the runner speed becomes almost equal to that of

the impeller only under the best operating conditions, when the efficiency of

liquid coupling is highest. But usually the runner speed is less than that of

the impeller. The (speed) lag of the runner behind the impeller is known as

slip. This (speed) slip varies with many factors such as engine speed, vehicle

speed and engine and vehicle load.

Fluid

Flywheel

15.2

Direction of fluid flow

Imagine tubes A

& B filled with fluid, A at N „rpm‟ & B at n „rpm‟.

• Let outer end C

of A closed with diaphragm.

• Let outer end D of B closed with diaphragm.

• Let

pressure exerted at C = pa

• Let pressure exerted at D = pb

• Therefore pa α N2

& pb α n2

• Therefore N > n, pa > pb

• So if diaphragm is removed

fluid flows from E to F.

• pa > pb so

fluid circulate between impeller & runner.

• Thus because of difference in

speed between impeller & runner, fluid circulates between impeller &

runner.

At K- fluid

particle at radius r

·

Rotates in a circle of radius r and angular speed of

N.

·

So linear speed = 2πr n

·

Therefore K.E at K = ½ w/g (2 r) 2

r) 2

·

Similarly K.E. at L = ½ w/g (2 R) 2

R) 2

·

Hence K.E.

at L > at K. So K.E of fluid is increased.

·

K.E. at M = ½

w/g (2 R) 2

R) 2

·

K.E. at M < K.E. at L (so some fluid lost)

·

K.E.s at N = ½ w/g (2 r) 2

r) 2

·

K.E. at N < K.E. at M

·

So fluid K.E

is transferred to runner.

·

Thus mechanical energy is transferred due to change

in K.E of rotating fluid.

15.3

Construction of Fluid Flywheel

A fluid Flywheel consists of three components, plus

the hydraulic fluid:

·

The housing, also known as the shell (which must

have an oil-tight seal around the drive shafts), contains the fluid and

turbines.

Two turbines (fan like components):

·

One connected to the input shaft; known as the pump

or impeller, primary wheel input turbine

·

The other connected to the output shaft, known as

the turbine, output turbine, secondary wheel or runner

Construction of

fluid Flywheel

15.4 Power transmission of Fluid Flywheel.

Fluid drive flywheel cannot achive 100% effficiency, but it

has much appreaciated effficiency of 98%. The equation for fluid flywheel

coupling & slip is discussed below.

Efficiency of fluid coupling = power at output/power at input.

η = (power transmitted to driven shat)/(power available to the

driving shaft)

Power at any shaft = 2 NT/60

NT/60

Sustituting this value in efficiency equation, Here “A” stands for diving

shaft “B” stand for driven shaft.

η = NB TB/NA TA

But the torque transmission is same TA=TB

Then efficiency η = NB/NA

15.5

FLUID USED IN FLUID FLYWHEEL

Servo Super Multi grade Oils are blended from

highly refined base stocks and balanced additive package containing shear

stable VI improver, metallic detergent dispersant and anti-oxidant. These oils

are formulated to meet lubrication requirements of both gasoline and diesel

engines. Servo Super Multi-grade Oils are red in colour and suitable for all

seasons. Mineral oils having low viscosity are used as working fluid SAE 10,

SAE 10w; oils are used in Fluid coupling

15.6

Design of fluid flywheel

Specific charge of

the working place is taken as, q

Speed of shaft np

Pump head (Hp) = ϼ

((P* η) 1/2/ np)

Shaft speed (m

rad/s).

Discharge flow =

P*η / P*G*Hp

Velocity of

meridian component = √ (2 * g *Hp)

Inlet and outlet

areas of impeller= Q/ cm

Diameter of

turbine = √ (g *Hp/ ω2 (1 - m2))

Impeller inlet

& outlet width = Q/ 2* 3.14 *re

No of blade on

impeller Z1

No of blade on

turbine Z2= Z1+2

Torque

calculation of Fluid Flywheel

Torque = force due

to mass X radial distance of force application

= F X R Where, F= force due mass = mg. R = distance of force application

Therefore Torque =

F R = m*g*R

Power transmitted=

2*π * N* T/60

15.7 Variation of Efficiency with speed ratio

·

When

starting from rest, efficiency = 0 i.e. both output speed and output are zero.

·

Efficiency = 0 when the load is removed,

runner is allowed to race.

·

As the runner gains speed, efficiency

increases.

·

Max

value of efficiency at design point (arbitrarily set).

·

Max

efficiency is of 85% to 90% based on 1.

No of stages 2. No of blades 3. Refinement of blades 4. Blades entrance &

exit angles

·

At a certain speed ratio, coupling point

output torque = input torque.

15.8 Variation of torque with speed

ratio

·

Output torque is max when starting α 1/ N2