Automobile chassis body & aerodynamics of vehicle

Automobile chassis body & aerodynamics of vehicle

1.1

Introduction

to chassis frame.

Chassis

is the French term which denotes the whole vehicle. A vehicle Frame also known

as its chassis, is the main supporting structure of a motor vehicle, to which all

other components are attached, comparable to the skeleton of an organism.

1.2

Layout

of chassis frame & its components.

Frame is a under carriage or structure that supports the engine &

cab (body) of the automobile. It is made up of long two members riveted

together with the help of number of cross members.

In automobile there are 3 major types of

construction based on frame.

Ø Conventional frame construction.

Ø Integral frame construction.

Ø Semi-integral frame construction.

Chassis layout Fig- 1.2

1.2. A. Conventional frame construction.

In this type of chassis the

body is made separate unit & then joined with ladder frame. It supports all

the system in a vehicle such as the engine, transmission system, steering

system, suspension system.

Advantages

·

Higher

load carrying capacity & strength.

Disadvantages

·

The

vehicle body tends to vibrate easily & the overall vehicle handling &

refinement is lower.

·

It is

used in truck, bus and in SUV cars bigger vehicles.

Conventional

chassis Frame Fig-1.2.A

1.2. B. Integral frame construction.

In some vehicle half frame

is fixed in the front end on which engine gear box & front suspension is

mounted.

Advantages

·

It has

the advantage when the vehicle is met with an accident the front frame can be

taken easily to replace the damage chassis frame.

·

This

type of frame is used in some of the European & American cars.

Integral Frame chassis construction Fig-1.2.B

1.2. C. Semi-integral frame construction.

This frame is used now days in

most of the cars. There is no frame and all the assembly units are attached to

the body. All the functions of the frame are carried out by the body itself.

Advantages

·

Due to

elimination of long frame it is cheaper & due to less weight most

economical also.

Disadvantages

·

The

disadvantage is repairing.

Semi-integral

chassis frame construction Fig- 1.2.C.

1.2. D. Different types of chassis

construction

A.

Composite

construction.

B.

Unibody

construction.

C.

Tubular

space frame

D.

Glass-fiber body

E.

Carbon-fiber Monocoque

chassis

F.

Aluminium

monocoque

G.

Ladder

chassis frame

A. Composite

construction

·

Composite

construction was the most common type of structure and on the earliest cars of

1900’s.

·

The

chassis & the body are built as the two separate units.

·

The

body is assembled on the chassis with mounting bracket.

·

These

flexible mountings allow the body to move slightly when the car is in motion.

Latest trends of composite construction

·

The

chassis structure contains the powertrain & mechanical components, while

the body is a separate structure.

·

There

are no mechanical links between the body & chassis, which makes it easy to

produce the rolling chassis in large quantities separate from the bodies, and

place different body styles on top of a common structure.

Composite chassis Frame

A. Tubular

space frame

·

Consists

of dozens of circular section tubes (uses square section tubes; for easier

connection to the body panels or circular section provides more strength.

·

High

performance cars require high strength.

·

Tubular

space frame chassis usually incorporate a strong structure under both doors.

·

Eg of

space frame construction is Audi A8, Audi R8, Ferrari 360, Lamborghini

Gallardo, Mercedes –Benz SLS AMG, Pontiac Fiero (GM motors) & Saturn s- series.

Tubular space Frame

Advantages

·

Very

strong in any direction. (Compare with ladder chassis & monocoque chassis

of the same weight).

Disadvantage

·

Very

complex, costly & time consuming to build.

·

Impossible

or mass production.

·

Raised

door sills result in difficult access to the cabin.

B .a. Ultra-light steel auto body

Advantages

·

Stronger

& lighter than conventional

Disadvantages

·

Not

strong & light enough for the best sport cars.

·

Same

structure as that of conventional monocoque.

·

Use of

hydro form parts, sandwiched steel & laser beam welding.

Ultra-light steel auto body

B. b. Aluminium

space frame

·

ASF

consists of extruded aluminium sections; vacuum die cast components &

aluminium sheets of different thickness.

·

At the

highly stressed corners & joints, extruded sections are connected by

complex aluminium die casting.

Advantages

·

Lighter

then steel Monocoque. As space efficient as it.

Disadvantages

·

Still expensive

for mass production.

B .c Lotus

aluminium space frame

·

Chassis

is made of extruded aluminium sections joint by glue & rivets.

·

Aluminium

extruded sections can be made much thinner then tradition welding techniques.

·

Welded

joints are weak, so the thickness of material should be increase throughout a

member just to make a joint strong enough.

Aluminium space frame

Advantages

·

Cheap

or low production. Offers the highest rigidity to weight ratio besides carbon

fibre monoloque.

Disadvantages

·

Not

very space efficient.

A.

Glass-Fiber

body

·

In 1957

lotus pioneered glass –fiber monocoque chassis is elite.

·

Whole

car weighted as light as 660kg.

Advantages

·

Lightweight.

·

Cheap

to be produced in small quantity.

·

Rust

proof.

Disadvantages

·

Lower

visual quality.

·

Unable

to act as stressed member.

Glass-Fiber body

A. Monocoque (Unibody)

·

Monocoque

construction was first widely used in aircraft , starting in the 1920’s

·

Introduction

of monocoque in automobiles in 1922 (Lancia lambda)

·

Monocoque

is one -piece structure which defines the overall shape of the car.

·

Made by

welding several piece together.

·

They

are spot welded together by robot arms (some even use laser welding) in a

stream production line.

·

After

that some accessories like doors, bonnets, boot lid, side panels & roofs

are added.

Monocoque chassis Frame

Advantages

·

Cheap

or mass production.

·

Inherently

good crash protection.

·

Space

efficient.

Disadvantages

·

It’s

very heavy.

·

Impossible

for small volume production.

A. Carbon

fiber monocoque frame

·

A unique and distinct appearance that’s nearly

impossible to replicate.

·

Excellent strength to weight ratio, compared to

other materials.

·

Suitable for complex contours and designs.

·

Superior fatigue properties.

·

High Stiffness.

·

High heat tolerances and resistance.

·

Flexible thermal and electrical properties.

·

Corrosion-resistance (with proper resins).

·

Varying classifications (tensile modulus) of

strength.

·

The strongest carbon fiber is 10x stronger and 5x

lighter than steel.

·

The strongest carbon fiber is 8x stronger and 1.5x

lighter than aluminium.

Carbon fiber monocoque frame

Disadvantages

·

One downside to

carbon fiber body is a lack of flexibility.

·

For instance a

metallic chassis can be heated and straightened or welded if it is slightly

bent or cracked.

·

Carbon fiber

will not bend, once the force of impact is large enough it will crack or

break and repairing it in most cases is not an option.

|

·

Carbon fiber can

be recycled but it loses its strength. Steel and aluminium can be recycled and

become just as strong and useful as it was before.

B.

Ladder chassis frame

It referred to as a

body-on-frame. It gets the ladder in its name from the way it looks. The frame

consists of two long, heavy beams of steel, held together by two shorter pieces.

Ladder chassis frame

Advantages

·

The reason it proved so popular, is its

simplicity.

·

A

ladder frame is easy to design, Build and can be used in multiple

applications with minimal modification.

·

Vehicles with a ladder frame are easier to

assemble, which means a manufacturer can charge less for them

·

heavier good for towing and durability

Disadvantages

·

The construction is heavier, bad for fuel

economy because of the extra weight. .

·

Poor resistance to torsion.

1.4. Various load & Forces acting on chassis

Frame.

Loads on the chassis frame

CHASSIS LOADING

i.

Longitudinal

Torsion

ii.

Vertical Bending

iii.

Lateral Bending

iv.

Horizontal

Lozenging.

i. Longitudinal Torsion

·

Application of

equal and opposite forces act at a certain distance from an axis tends to

rotate the body about the same axis.

·

The frame can be thought as a torsion spring

connecting the two ends where suspension loads act.

·

The resistance to

torsional deformation is called as stiffness and it is expressed in Nm/degree

in SI units.

·

Torsional rigidity is a foremost and primary

determinant of frame performance of cars.

longitudinal Torsion

II. Vertical Bending

·

Weight of driver,

engine, drive-train, radiator and shell etc. under an effect of Gravity produces

sag in the frame as shown in Figure 2.

·

Frame is assumed

to act as simply supported beam and four wheels as supports tend to produce

reactions vertically upward at the axles.

·

Vertical dynamic

forces due to acceleration/deceleration further increase the vertical

deflections, hence stresses in chassis.

Vertical Bending

III. Lateral Bending

·

Lateral bending

deformation occurs mainly due to the centrifugal forces caused during Cornering

and wind forces to some extent.

·

Lateral forces act

along the length of chassis and is resisted by axles, tires and frame members viz.

hoops, side impact members and diagonal hoops etc.

Lateral Bending

IV. Horizontal Lozenging.

·

This deformation

is caused by forward and backward forces applied at opposite wheels

·

These forces may

be caused by vertical variations in the pavement or the reaction from the road

driving the car forward.

·

These forces tend

to distort the frame into a parallelogram shape as shown in the Figure.

·

The magnitude of these loads changes with the

operating mode of the car.

·

It is generally

thought that if torsional and vertical bending stiffness is satisfactory, then

the chassis structure is expected to perform well. But torsional stiffness is

given more weight-age as the total cornering traction is the function of

lateral weight transfer.

Load acting on the frame

·

Material properties

of the Truck Chassis (high strength structure steel)

Material Properties

·

Young Modulus 200GPa

·

Poisson Ratio 0.33

·

Density

7827.08kg/m3

Symmetry Linear isotropic 76

In the finite element analysis

of the truck chassis, the linear

Isotropic material model of

high strength structural steel was used.

OVER ALL DIMENSIONS OF THE CHASSIS

All over length :

7956 mm

All over width : 4400

mm

All over height : 4500 mm

Wheel base: 4100 mm

Wheel tread: 3450 mm

·

Weight of the

Vehicle

·

Total Weight of

the Vehicle and Payload.

Pay load

|

534645N

|

NVW

|

426735 N

|

Maximum GVW

|

961380 N

|

Convert =kg X 9.81=N

3.3.1 Calculation of Bending

and Torsion Case Load

Consider a simply supported

beam.

FFT =

F1V + F2V

FRT =

F3V + F4V

Where, WB =

Wheel Base

FFT =

Force at Front Tire

FRT

= Force at Rear Tire

According to the equation of

equilibrium condition

∑H = 0, ∑V = 0, ∑M = 0

Force

at front tire (FFT).

2/3

WB =0.66x4100= 2706 mm

1/3

WB = 0.33 x 4100=1366 mm

Taking

moment at front (F) i.e. MF = 0

FRT × 4100 = 961380

x2706

FRT =

961380x2706/4100= 634510N

Force at front tire (FRT).

Taking

moment at front (F) i.e. MR = 0

FFT × 4100 = 961380

x1366

FFT = 961380 x

1366/4100= 320303N

·

Bending

load acting on the frame.

Assume around 24 bolts used on Front side

& 4 used on rear side

·

Front

suspension load at each bolt: FFT = 320303/24=13345N.

·

Rear

suspension load at each bolt: FRT = 634510/4=158627N

Torsion Load acting on the frame

Load distribution of the tire for torsion load conditions

Torsion Load acting on the frame

Right ramp loading.

F1v

= 0 N

FFT

= F1v + F2v

FFT = F2v = 320303N

F4v × RT = (GVW x

RT/2) + {RT+ (FT-RT)/2 F2v}

Taking moment at a

rear right tire point i.e. (M F4v = 0)

Left

Ramp Loading

F2v

= 0 N

F3v

× RT = (GVW x RT/2) - (F2v) x (FT-RT)/2 +RT

F

RT = F3V + F4V

GVW

= 961380 N

RT

=2920 mm

FT = 3480 mm

F2v =

320303 N

F4v × RT = (GVW x

RT/2) + {RT+ (FT-RT)/2 F2v}

F4v × 2920 =

(961380 x 2920/2) + {2920+ (3480-2920)/2 x 320303}

F4V ×2920 =1403614800+89687760

F4V = 511404.9N.

160250

= F3V + 511404

F3V = 160250 –

511404

F3V= -351154N.

1.5 Explain different types of drive train.

1.5. A. Front-wheel-drive layouts

Front-wheel-drive

layouts are those in which the front wheels of the vehicle are driven. The most

popular layout used in cars today is the front-engine, front-wheel drive – with

the engine transversely in front of the front axle, driving the front wheels.

·

Advantages of FWD

Front-wheel-drive layouts

·

Interior space:- Since the powertrain is a

single unit contained in the engine compartment of the vehicle, there is no

need to devote interior space for a driveshaft tunnel

or rear differential, increasing the volume available for passengers and

cargo.

·

Weight: - Fewer components usually mean lower

weight. Improved fuel efficiency due

to less weight.

·

Cost: -

Fewer material components and

less installation complexity overall.

·

Improved drivetrain efficiency:- the direct connection between engine and transaxle

reduce the mass and mechanical inertia of the

drivetrain compared to a rear-wheel-drive vehicle

·

Assembly efficiency: - the powertrain can

often be assembled and installed as a unit, which allows more efficient

production.

·

Traction: - Placing the mass of the

drivetrain over the driven wheels moves the centre of gravity farther

forward than a comparable rear-wheel-drive layout, improving traction and

directional stability on wet, snowy, or icy surfaces.

Disadvantages of FWD

·

Front-engine front-wheel-drive layouts are

"nose heavy" with more weight distribution forward, which makes them

prone to under steer,

especially in high horsepower applications.

·

Torque steer is the

tendency for some front-wheel-drive cars to pull to the left or right under

hard acceleration

·

In a vehicle, the weight shifts back during

acceleration, giving more traction to the rear wheels. This is one of the main

reasons nearly all racing cars are rear-wheel drive.

·

Turning circle – FWD layouts almost

always use a transverse engine ("east-west")

installation, which limits the amount by which the front wheels can turn, thus

increasing the turning circle of a front-wheel-drive car compared to a

rear-wheel-drive one with the same wheelbase.

·

The FWD transverse engine layout

(also known as "east-west") restricts the size of the engine that can

be placed in modern engine compartments, so it is rarely adopted by powerful

luxury and sports cars.

·

It makes heavier use of the front tyres

(i.e., accelerating, braking, and turning), causing more wear in the front than

in a rear-wheel-drive layout.

1.5. B. Rear -wheel-drive layouts

Rear-wheel

drive (RWD) typically places the engine in the front of the vehicle and the

driven wheels are located at the rear, a configuration known as front-engine, rear-wheel-drive layout (FR

layout).

Rear -wheel-drive layout

Advantages of RWD

·

Weight transfer during

acceleration – During heavy acceleration, weight is placed on the rear, or

driving wheels, which improves traction.

·

Better braking – the more even weight

distribution helps prevent lockup from the rear wheels becoming unloaded under

heavy braking.

·

Can accommodate more powerful engines as a

result of the longitudinal

orientation of the drivetrain, such as the inline-6, 90°

big-bore V8, V10 and V12 making

the FR a common configuration for luxury and sports cars.

·

Road grip feedback – front wheels are

not affected by engine and gearbox, thus allowing for better feeling of tyre

grip on road surface.

Disadvantages of RWD

·

Under heavy acceleration (as in racing), over

steer and fishtailing may

occur as the rear wheels break free and spin.

·

On snow, ice and sand, rear-wheel drive loses

its traction advantage to front- or all-wheel-drive vehicles, which have

greater weight on the driven wheels.

·

Decreased interior space – Though

individual designs vary greatly, rear-wheel-drive vehicles may have: Less front

leg room as the transmission tunnel takes up a space between the driver and

front passenger, less leg room for centre rear passengers.

·

Increased weight – The components of a

rear-wheel

-drive vehicle's power train are less complex, but they are larger.

The driveshaft adds weight.

·

Higher initial purchase price – Modern

rear-wheel-drive vehicles are typically more expensive to purchase than

comparable front-wheel-drive vehicles.

1.5. C. Four wheel drive layout

Four-wheel drive,

also called 4×4 ("four

by four") or 4WD

refers to a two-axle vehicle drivetrain capable

of providing torque to all

of its wheels simultaneously. It may be full-time or on-demand, and is

typically linked via a transfer case providing

an additional output drive-shaft and, in many instances, additional gear ranges.

Four wheel drive layout

Advantages of 4WD

·

Traction is nearly doubled compared to a

two-wheel-drive layout. Given sufficient power, these results in unparalleled

acceleration and driveability on surfaces with less than ideal grip, and

superior engine braking on loose surfaces.

·

A well-balanced 4WD configuration will not

degenerate into either under steer or over steer, but instead break traction of

all 4 wheels at the same time into a four-wheel drift.

Disadvantages of FWD

- 4WD systems require more machinery and complex transmission components, and so increase the manufacturing cost of the vehicle and complexity of maintenance procedures and repairs compared to 2WD designs

- 4WD systems increase powertrain mass, rotational inertia and power transmission losses, resulting in a reduction in performance in ideal dry conditions and increased fuel consumption compared to 2WD designs

- The handbrake may not be used to induce over steer for manoeuvring purposes, as the drivetrain couples the front and rear axles together. To overcome this limitation, some custom prepared stage rally cars have a special mechanism added to the transmission to disconnect the rear drive if the handbrake is applied when the vehicle is moving.

1.5. D. Individual Wheel Drive (IWD)

IWD is the drivetrain used in

most electric cars, which are gaining more popularity as we are heading towards

an electric car-driven world the figure below shows individual wheel

drive system. As each wheel is powered by a separate motor, greater traction.

Individual

Wheel Drive (IWD

Advantages

of individual wheel drive (IWD)

·

Control is achieved, compared to Front wheel

drive or Rear wheel drive, in which, the non-powered wheels also.

·

Contribute to the resistance but doesn’t contribute

much to traction. The gears are only used to increase the torque.

·

An Electric vehicle with individual wheel

drive has greater control. These vehicles don’t need long and heavy duty

·

It provides

sportier handling and traction for a wide range of car

Disadvantages

of individual wheel drive (IWD)

·

It increases fuel consumption.

·

It increases the complexity and weight of cars.

·

It is not suitable for extreme off-road condition.

1.6.

Different types of cars.

a.

Convertible

·

A convertible is a car which features a

retractable roof – in other words, a roof that can be folded down or removed

either partially or in its entirety.

·

Convertible cars have a roof which may either

be folded via an electronic or manual mechanism, or alternatively the top roof

panel may be removable and stored in a compartment somewhere when the driver

wants to experience open-top driving.

·

E.g. Mazda MX-5, Porsche 718 Boxster, Audi A3, Mercedes E-Class, Porsche 911

, Audi A5 Cabriolet, Jaguar F-Type, BMW 4

Series Convertible.

Convertible

bb. SUV cars

•

An SUV is a

passenger vehicle, which combines the towing capacity of a pickup truck with

the passenger-carrying space of a sedan.

•

They have a

powerful engine, have sufficient passenger space along with luggage compartment

behind the rear row seats and are designed for all terrains.

•

They are

non-commercial vehicles with the BIW built on the chassis similar to a light

truck or a crew cab

•

An off roader

needs a long hood and an upright position. That lends the Vehicle

self-assuredness and power.

•

E.g.- Maruti Suzuki Vitara, Mahindra KUV100 Facelift, Mitsubishi Pajero Sport

Facelift, BMW X2, Nissan Qashqai, Isuzu MU-X Facelift 2018.

·

Coupes are stylish cars best for singles or

couple

·

The doors tend to be wider and the roof

lower. It is shorter than a sedan and may or may not have a back seat. If there

is back seating, it might be a little tighter than you may find comfortable.

·

E.g. - Mercedes-Benz, Mercedes-AMG C-Class: Recall

Alert, Mercedes-AMG S63, Maserati GranTurismo, Lexus, Subaru.

coupe car

d. Hatchback cars

·

A hatchback is smaller than an SUV or minivan, but

larger than a sedan. The main difference between a hatchback and a sedan is the

extended trunk. Instead of the back sloping downwards, the back area is lifted,

providing extra space for cargo.

·

Typically, the hatchback has a top-hinged trunk

with rear seats that fold down for even more cargo space. As a result,

hatchbacks are usually marketed as small family cars or executive cars.

·

Since the interior space can be made to prioritize

passengers or cargo, they are a popular and practical choice for those who need

both. From small city hatchbacks to large luxury models, there is a wide

variety of hatchbacks available to you.

·

E.g. Maruti Swift, Maruti Baleno, Maruti Alto, Hyundai Elite i20,

Renault KWID. Maruti Wagon R.

Hatchback cars

e. Sedan cars

·

A sedan, also known as a saloon in other

countries, is the most popular body style. It typically features two rows of

seats, 4 doors, and a 3-box configuration.

·

Sedans tend to provide better fuel economy,

affordability, handling, and performance.

·

Since they are closer to the ground and have

a lower centre of gravity, they tend to perform better around corners and sharp

turns than larger vehicles such as SUVs. As a result, they are much less prone

to tipping and rolling over than trucks and SUVs.

·

E.g. Fiat Viaggio, Tata

Tiago EV, Renault Talisman, Volvo C70, Hyundai

Sonata Facelift, Honda Civic.

Sedan cars

f. Crossover cars

·

A cross between a sedan and an SUV,

crossovers (also known as Crossover Utility Vehicles) give you the best of both

worlds.

·

They are available in four-wheel, rear-wheel,

and all-wheel drives.

·

They are cheaper and have better fuel economy

than full-sized SUVs while still giving you extra ground clearance and a more

commanding view of the road.

·

E.g. Mahindra U321 MPV, Mahindra TUV300

Plus, Nissan Kicks, Renault Duster facelift, Tata Q501 (codename), MG GS

Concept, Datsun Go-Cross.

Crossover cars

g. Electric cars

The

heart of an electric car is the combination of:

·

The motor's controller

·

The batteries

The

controller takes power from the batteries and delivers it to the motor. The accelerator pedal hooks to a pair of potentiometers (variable resistors), and these potentiometers

provide the signal that tells the controller how much power it is supposed to

deliver. The controller can deliver zero power (when the car is stopped), full

power (when the driver floors the accelerator pedal), or any power level in

between.

E.g. - Tata Tiago, Tata Tigor, Renault Zoe, Mercedes-Benz EQ Concept, Hyundai

Ioniq

Advantage of Electric Vehicle

·

Zero emission

·

Power Regeneration

·

Low noise pollution

·

Instant start and direct drive.

Disadvantage of Electric Vehicle

·

Limited

Range

·

Long

Refuelling Time

·

Higher

Cost

·

Lack of

Consumer Choice

h. Fuel Cell

Electric Vehicle (FCEV)

·

FCEVs also go by the name Fuel Cell Vehicle

(FCV).

·

They got the name because the heart of such

vehicles is fuel cells that use chemical reactions to produce electricity.

·

Hydrogen is the fuel of choice for FCVs to

carry out this reaction, so they are often called ‘hydrogen fuel cell

vehicles’.

·

FCVs

carry the hydrogen in special high pressure tanks, another ingredient for the

power generating process is oxygen, which it acquires from the air sucked in

from the environment.

·

Electricity generated from the fuel cells goes

to an electric motor which drives the wheels. Excess energy is stored in

storage systems like batteries or super capacitor

·

E.g. Hyundai Tucson Fuel

Cell, Toyota Mira, Honda Clarity Fuel Cell.

Working

·

The Fuel gas (hydrogen rich) is passed towards the

anode where the following oxidation reaction occurs:

H2 (g) = 2H+ + 2e-

·

The liberated electrons from hydrogen in anode side

do not migrate through electrolyte.

·

Therefore, they pass through the external circuit

where work is performed, then finally goes into the cathode.

·

On the other hand, the positive hydrogen ions (H+)

migrate across the electrolyte towards the cathode

·

At the cathode side the hydrogen atom reacts with

oxygen gas (from air) and electrons to form water as byproduct according to:

·

The liberated electrons from

the hydrogen are responsible for the production of electricity.

·

The

water is produced by the combination of hydrogen, oxygen and liberated

electrons and is sent out from the cell.

·

The

DC current produced by fuel cell is later converted into AC current using an

inverter for practical application.

·

The

voltage developed in a single fuel cell various from 0.7 to 1.4 volt.

·

More

power can be obtained by arranging the individual fuel cell as a stack. In this

case, each single cell is sandwiched with one another by a interconnect.

Advantages

·

Zero Emissions: a fuel cell vehicle only

emits water vapors. Therefore, no air pollution occurs.

·

High efficiency: Fuel cells convert chemical

energy directly into electricity without

the combustion process. As a result, Fuel cells can achieve high efficiencies

in energy conversion.

·

High power density: A high power density allows

fuel cells to be relatively compact source of electric power, beneficial in

application with space constraints.

·

Quiet operation: Fuel cells can be used in

residential or built-up areas where the noise pollution can be avoided.

·

No recharge: Fuel cell systems do not

require recharging.

Disadvantages

·

It is difficult to manufacture and stores a high

pure hydrogen

·

It is very expense as compared to battery

I . Hybrid cars

A hybrid vehicle uses

two or more distinct types of power, such as internal combustion engine to

drive an electric

generator that powers an electric, e.g. in diesel-electric

trains using diesel engines to drive an electric generator that

powers an electric motor, and submarines that use diesels when surfaced and

batteries when submerged. Other means to store energy include pressurized fluid

in hydraulic hybrids.

E.g. - Toyota Camry Hybrid,

Toyota Avalon Hybrid, Chevrolet Bolt, Ford

Fusion Hybrid, Toyota Prius, Kia Optima Hybrid, Hyundai Ioniq, Honda

Accord Hybrid. Find Best Price.

I.

Series hybrid cars

The series hybrid has the generator driven by the engine. This generator

is used to charge the batteries and also drive the electric motor, which drives

the transmission. Thus power to the vehicle is never directly given by the

engine.

II.

Parallel hybrid cars

In a parallel hybrid vehicle an electric motor and an

internal combustion engine are coupled such that they can power the vehicle

either individually or together. Most commonly the internal combustion engine,

the electric motor and gear box are coupled by automatically controlled

clutches. For electric driving the clutch between the internal combustion

engine is open while the clutch to the gear box is engaged. While in combustion

mode the engine and motor run at the same speed.

Advantages of Hybrid Cars

·

Very less pollution.

·

Better mileage.

·

More reliable and comfortable.

·

Very clean cars due to less emission.

·

Batteries need not be charged by an external

source.

·

Warranties ava

·

Less dependence on fuels.

Disadvantages

of Hybrid Cars

·

The initial cost will be very high – higher than

other cars.

·

Since a lot of batteries will be needed, the car

will be very heavy.

·

As there are electrical components, there is risk

of shock during an accident.

·

The vehicle can be repaired only by professionals.

·

Spare parts will be very costly and rare.

Power transmission

1.7 Aerodynamics of a car body

A branch of

dynamics that deals with the motion of air and other gaseous fluids and with

the forces acting on bodies in motion relative to such fluids.

1.7. a. Advantages of aerodynamics

It is essential that

aerodynamics be taken into account during the design of cars as an improved

aerodynamics in car would attain.

·

More

fuel efficiency

·

Higher

speeds

·

Good

aesthetics & stylish appearance of car

·

More

stability of car at higher speed

·

Reduces

noise level

1.7. b. Methods of

Aerodynamic Testing

The two main

alternative test methods, which are the most commonly used in aerodynamic

development and testing of cars, are Computational Fluid Dynamics (CFD) and

wind tunnel testing.

·

Wind

tunnel Testing

Wind tunnel testing has the big

advantage that once the vehicle model is produced and rigged in the wind tunnel

test section, it can quickly provide highly accurate data. Data for different

boundary conditions, such as different wind speeds and yaw angles, can be

acquired quickly. If similar changes in conditions are done on a computer

model, the whole simulation has to be run over again for each case. On the other

hand, wind tunnel testing can

be both highly costly

and time consuming.

Open & close circuit wind tunnel testing

Open & close circuit wind tunnel testing

·

Computational Fluid

Dynamics

Computational fluid dynamics (CFD) is one of the branches of fluid

mechanics that uses numerical methods and algorithms to solve and analyse

problems that involve fluid flows. Computers are used to simulate the interaction

of liquids and gases with surfaces defined by boundary conditions. Even with high-speed supercomputers only approximate

solutions can be achieved in many cases.

1.7. c. Aerodynamics forces acting on body

In order to improve the aerodynamics

of cars, we must know how the flow of air past a car. The major forces which

affecting the motion of car in fluid flow are.

·

Drag

force

·

Lift or

down force

·

Side

force

·

Drag force

Some energy is lost to move the car

through the air & this energy is used to overcome a drag force. In vehicle

aerodynamics drag is due to frontal pressure & Rear vacuum.

For calculating drag force following formula

is use

F= ½ CDAV2

Where F=

Aerodynamics drag force A= frontal area

C=coefficient of drag V=velocity of object

D= density off air

·

The drag coefficient is a function of the shape

of the object and the Reynolds Number (Re)

·

Re = (velocity * length-scale) / (kinematic

viscosity)

·

There are several good ways to calculate the

frontal area of your vehicle. One is to simply measure the height multiplied by

the width and take 85% of it to acuminate the smaller green house.

F.A. = (height x width) x 0.85

F.A. = (height x width) x 0.85

Calculating drag force for Toyota Prius C

Dimensions

Wheel base - 2550mm

Length – 4000mm

Width – 1690mm

Height – 1450mm

F drag =1/2 x δxV2 x D x A

T air = 670F

T0C = (T0F

– 32) x (5/9) = (67-32) x (5/9) = 19.40C

Ꝭ = density of air =1.204 kg/m3

at 19.40C temp

D= drag coefficient for Toyota Prius C = 0.28

A= Frontal area of Car = W x H x 0.85 = 1690 x 1450 x 0.85= 2.0336m2

V= 6km/hr. x 1hr/3600sec x 1000/1km = 1.6Km/hr.

F drag =1/2 x 1.204 x (1.6)2 x 0.28 x 2.0336 = 0.87461W

Y=0.2275 X2 +0.3187X

(as per equation y=ax2+bx)

As the car is moving 30km/hr from 0 to 9.25sec

F drag =0.2275 t2 +0.3187t

9.25 9.25

9.25

ʃ F drag dt = ʃ

(0.2275t2 + 0.3187

t ) dt = [ 0.2275t3/3 + 0.3187t2/2]

0 0

0

=73.653N.S

9.25

F drag

= ʃ F drag dt /Δt = 73.653/9.25 = 8N

0

·

Lift force

It is the force produced by the

pressure difference between above & below of the vehicle.

(FL) = CL q A = (CL (1/2) r V2)

A

Where

CL =

Coefficient of Lift

q = Dynamic Pressure in the Test Section

r = Mass Density of Air

A = Frontal Area of Vehicle

V = Velocity

q = Dynamic Pressure in the Test Section

r = Mass Density of Air

A = Frontal Area of Vehicle

V = Velocity

·

Side force

It is produced by the action of

side winds.

(FS) = CS q A = (CS (1/2) r

V2) A

Where

CS =

Coefficient of Side Force

q = Dynamic Pressure in the Test Section

r = Mass Density of Air

A = Frontal Area of Vehicle

V = Velocity

r = Mass Density of Air

A = Frontal Area of Vehicle

V = Velocity

1.7. f. METHODS TO REDUCE DRAG

·

Vortex Generators

·

Diffuser

·

Rear Fairing

·

Streamlining

·

Spoilers

·

Vortex

Generators

A vortex

generator (VG) is an aerodynamic device, consisting of a small vane usually

attached to a lifting surface (or airfoil, such as an aircraft

wing) or a rotor blade

of a wind turbine. VGs may also

be attached to some part of an aerodynamic vehicle such as an aircraft fuselage

or a car. When the airfoil or the body is in motion relative to the air, the VG

creates a vortex, which, by removing

some part of the slow-moving boundary layer

in contact with the airfoil surface, delays local flow separation and aerodynamic

stalling, thereby improving the effectiveness of wings and control surfaces,

such as flaps, elevators, ailerons, and rudders. If the air that makes up the vortex can be tripped before it leaves

back of the car, it will make smaller vortices, which will have a smaller

effect on the overall aerodynamics of the vehicle.

Bump shape vertex generator

·

Concept of a Vortex

The laminar boundary layer flow is a

very smooth flow, with no disruption between the layers. It has low skin

friction drag but it is unstable, which means that flow separation is easier

when it has laminar behavior at high angles of attack. Laminar flow airfoils tend to provide low

drag at cruise but nasty stall characteristics. Turbulent boundary layer is

characterized by chaotic property changes. The flow has more energy and has

rapid variations of pressure and flow velocity in space and time - turbulence is complex and therefore

turbulent flow is more complex to simulate. In turbulent flow, drag caused by

boundary layer skin friction increases. shows a good intuitive approach of the

transition process.

Vertex

flow of Air

·

Diffusers

It works by providing a space for the

under body airflow to decelerate and expand (in area, as density is assumed to

be constant at the speeds that cars travel) so that it does not cause excessive flow

separation and drag, by providing a degree of "wake infill" or more accurately, pressure recovery. The diffuser itself accelerates the

flow in front of it, which helps generate down

force.

Diffusers

· Operation

The

pressure under the car is affected by the diffuser so that it can expand back

to ambient in the diffuser, as the car moves through the air. It uses Bernoulli's principle, such that the pressure decreases while

the velocity increases. Since the pressure below the car is lower than on the

side and above the car, down force is produced if implemented correctly. The

diffuser "drives" the under body, which produces the down force.

·

Rear

Fairing

A structure on various parts of

a vehicle, for example an aircraft, automobile, or motorcycle, that produces a smooth exterior and

reduces drag.

Rear fairing in jet

·

Streamlining

A streamlined body is a shape

that lowers the friction

drag between a fluid, like air and water, and an object moving through that

fluid. Drag is a force that

slows down motion; friction drag is a special kind of drag. It occurs when the

fluid closest to the object sticks to its surface, exerting a force that

opposes the object’s motion.

Particles of a

continuous fluid can be considered to travel along smooth continuous paths

which are given the name streamlines.

These streamlines can be curved or straight, depending on the flow of

the fluid. This type of motion is also called laminar flow. Streamline motion

is not the only possible kind of fluid motion.

When the motion becomes too violent, eddies and vortices occur. The motion becomes turbulent.

Streamlining

·

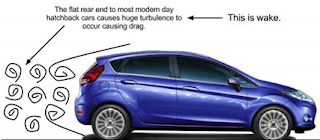

Effect of wake on streamlining

The rear-end shape of a car is one of the most important parts

from the view point of aerodynamics. It governs the aerodynamic characteristics

of the car, especially drag and rear lift. However, a rear-end shape like a

spoiler often increases drag on recent low-drag cars. The relation of rear-end

shape to drag and lift is studied by consideration of the wake structure, which

is obtained by wind tunnel testing and CFD. Finally, a new rear shape which

reduces rear lift without increasing drag and front lift is discussed

Effect of wake

·

Spoilers

A spoiler is an automotive

aerodynamic device whose intended design function is to “spoil” unfavorable air

movement across a body of a vehicle in motion, usually described as drag.

Spoilers on the front of a vehicle are often called air dams, because in

addition to directing airflow they also reduce the amount of air flowing

underneath the vehicle, which generally reduces aerodynamic lift and drag.

Spoilers are often fitted to race and high-performance sports cars, although

they have become common on passenger vehicles as well. Some spoilers are added

to cars primarily for styling purposes and have either little aerodynamic

benefit or even make the aerodynamics worse.The goal of many spoilers used in

passenger vehicles is to reduce drag and increase fuel efficiency. Passenger

vehicles can be equipped with front and rear spoilers. Front spoilers, found

beneath the bumper, are mainly used to decrease the amount of air going

underneath the vehicle to reduce the drag coefficient and lift. Sports cars are most commonly seen with front

and rear spoilers.

Spoilers

·

CFD(Computational fluid dynamics)

“CFD

(Computational fluid dynamics) is a set of numerical methods applied to obtain

approximate solution of problems of fluid dynamics and heat transfer.”

The

physical characteristics of the fluid motion can usually be described through

fundamental mathematical equations, usually in partial differential form, which

govern a process of interest and are often called governing equations in CFD. The computational part simply means the study

of the fluid flow through numerical simulations, which involves employing

computer programs or software packages performed on highspeed digital computers

to attain the numerical solutions.

CFD

codes are structured around the numerical algorithms that can handle fluid flow

problems. All the CFD commercial packages available in the market have three

basic elements, which divide the complete analysis of the numerical experiment

to be performed on the specific domain or geometry. The three basic elements

are

I .

Pre-processor

ii. Solver

iii. Post-Process

Very nice blog. Easy to understand.

ReplyDeleteWell done...

ReplyDeleteSir, tuition lete ho kya